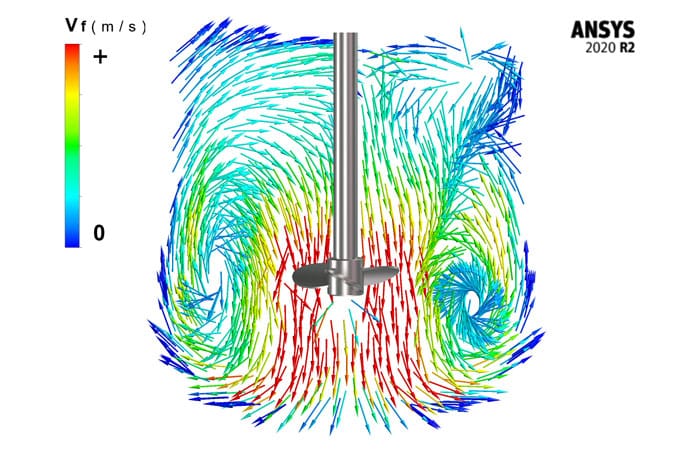

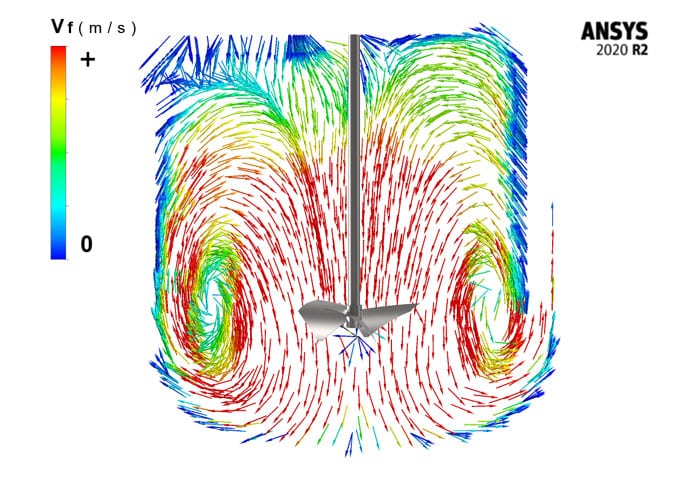

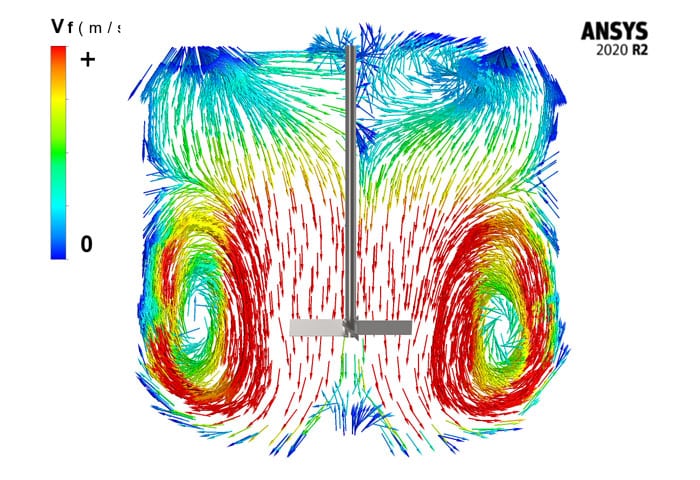

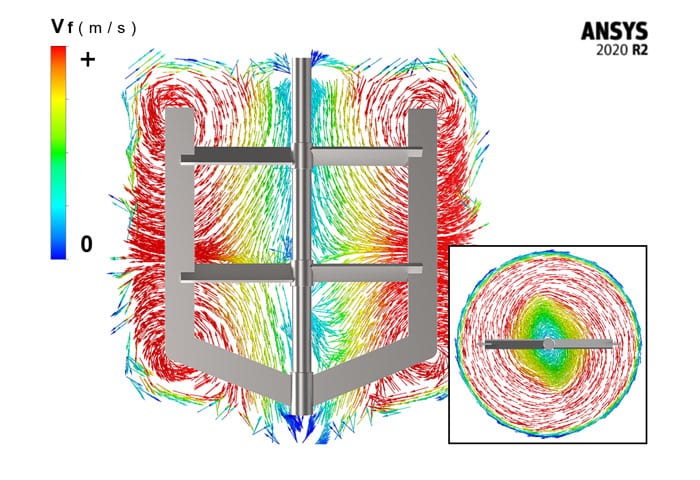

Industrial processes are comprised of a set of operations designed to transform raw materials into one or more products. Almost all industrial processes involve some form of mixing consisting of the generation of a certain flow inside a tank (open or closed) using the rotating movement of one or more propellers.

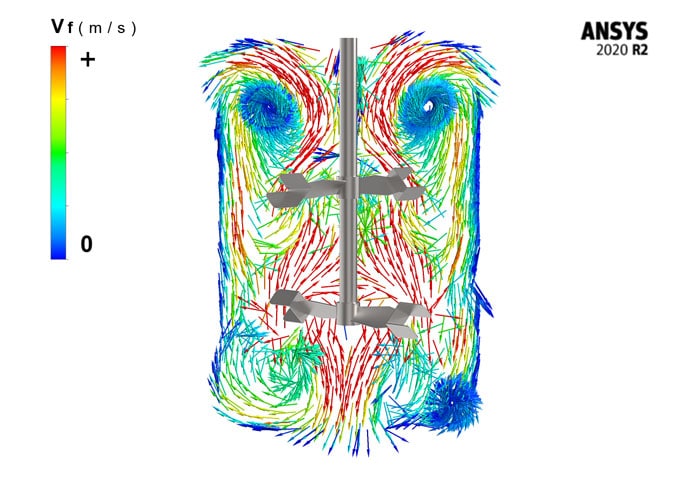

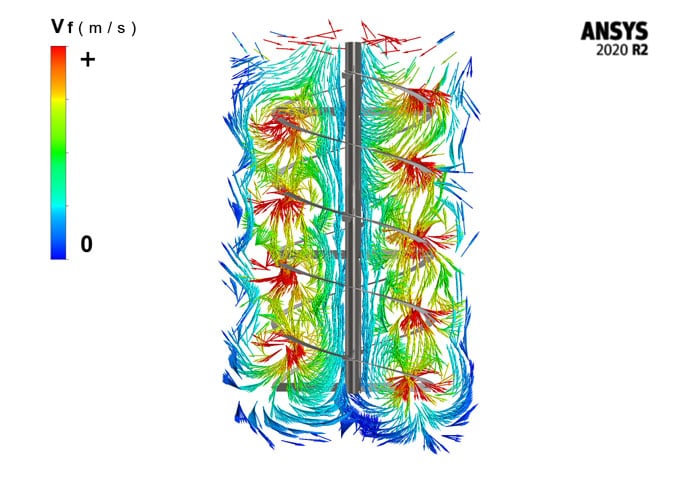

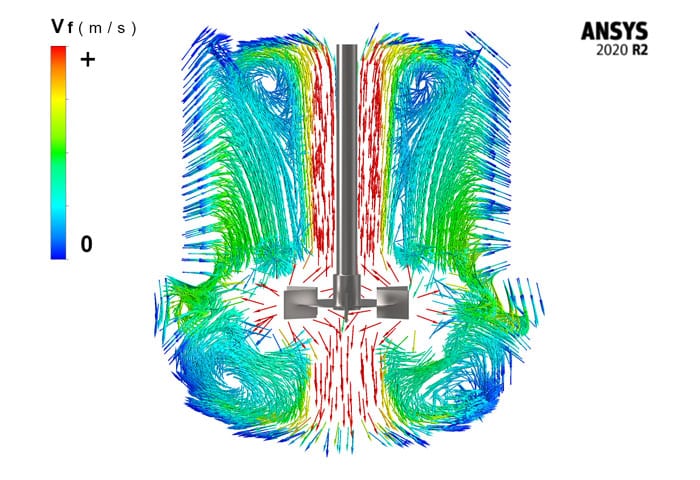

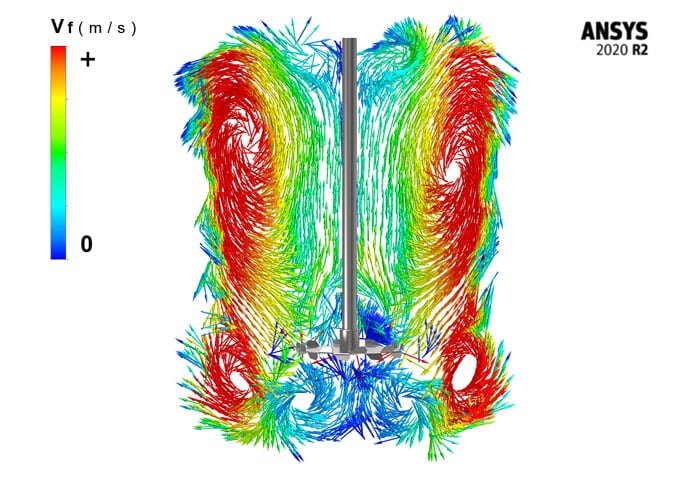

When mixing is required in an industrial process, the system must be developed through a normally cylindrical tank and an industrial stirrer (a set consisting of drive, a shaft, and one or more impellers along the shaft).

For the optimal design of the mixing system, it should be taken into account in addition to the basic mixing functions of the selected agitator (type, number and diameter of impellers, turning speed and engine power), the operating conditions of the process (product properties to be mixed, continuous or discontinuous operation, recirculation, batch or semi-batch, liquid level variations, ..) as well as tank geometry (dimensions, Baffle, heat exchangers, inlet and outlet connections…)